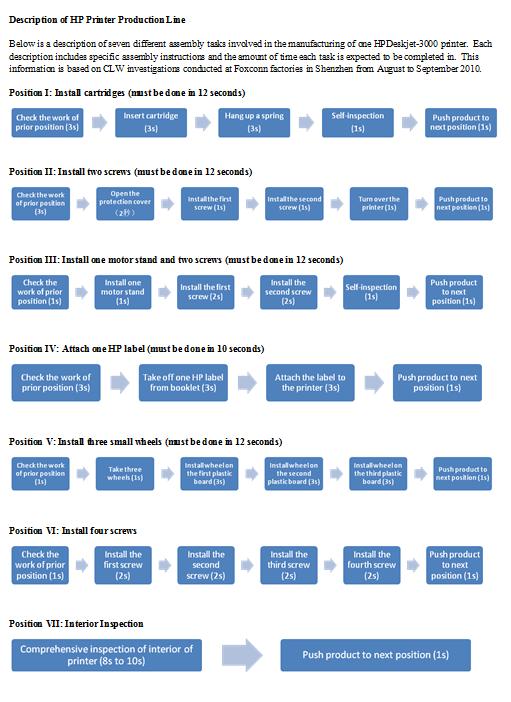

Description of HP Printer production line

New York– Foxconn’s goal to replace existing workforce with 1,000,000 assembly robots over three year period is a unfeasible plan says China Labor Watch executive director Li Qiang.

According to media reports, Foxconn plans to install 1,000,000 Robots within the next three years in order to replace the bulk of their existing labor force and reduce overall labor costs. China Labor Watch (CLW) demands Foxconn to improve its labor treatment rather than simply replacing workers with robots. CLW believes that Foxconn will not be able to achieve this goal within this short period of time for the following reasons:

1) Particularly complex labor processes cannot be fully completed by using only robots

In the past, CLW sent investigators into Foxconn’s factories to observe their assembly line manufacturing methods. There is an enormous amount of labor intensity required to manufacture one HPDeskjet-3000 printer. The assembly line consists of around 150 workers, who produce approximately 3,000 printers per day. On average, each task on the assembly is completed in 12 seconds. Many of these tasks are particularly complex and it would be impossible to have only robots complete them. We have given examples of 7 assembly tasks that we believe could not be solely completed by robots. Please view the attached document below for information regarding these 7 assembly tasks. Other manufacturing workshops have even more complex assembly tasks, which could not be completed solely through robot labor.

2) Robots will not be able to keep up with rapid turnover rate for electronic products

The turnover rate for the introduction of new and updated electronic products is very high. Every new change of an electronic product, however small, has a great effect on the electronic manufacturing process, often resulting in changes to assembly line production. These changes in the manufacturing process would ultimately leave assembly line robots unusable and outdated, unless they were equally updated to perform these new assembly tasks. This undertaking would most definitely come at a financial cost that Foxconn would not be able or willing to bear.

3) Electronic products have a short delivery window that must be met. However, these robots still need to be tested on the assembly line, which would make it initially impossible for the factory to meet customer’s delivery dates.

CLW executive director, Li Qiang, believes, “There is a large turnover rate for Foxconn workers because of the increased militarized way in which they are managed by factory officials. This high turnover rate is a primary reason Foxconn has had difficultly recruiting workers and is now considering installing assembly robots. The crucial factor here is the treatment of Foxconn workers. Foxconn must decrease the labor intensity workers work under and provide each worker with the ability to live a dignified life, in order to keep them working in the factories.