(After a toxic gas poisoning took place at Catcher Technology's A6 workshop, Catcher was directly ordered by the local government to cease operations in the toxic workshop. In spite of the official order, Catcher ignored the request, resulting in an additional 30 workers falling poisoned and increasing the total number of poisoned workers to over 90)

( Besides for the toxic gas, doctors also attribute the long work hours at Catcher, which are in clear violation of local labor laws, to be an attributing factor to the workers' conditions.)

Apple denied any previous knowledge of the toxic gas incident that took place at Catcher Technology on May 2017 and claimed they found no evidence for the other violations to their supplier responsibility standards as described in our January 2018 report,

Apple’s Failed CSR Audit. In response to Apple’s denial of the violations found by China Labor Watch (CLW), below is a list of violations compiled from news articles written by two independent sources, Jiangsu News 360 and Bloomberg Technology, as well as a further reiteration of the violations discovered by CLW. These journalists conducted their own interviews with workers and their findings echo the ones detailed in CLW’s report.

If two news outlets have, in their separate investigations, discovered the same violations CLW has, then how come Apple’s own audits have not produced similar results? Apple has stated that they have employees stationed at all of their supplier factories. If so, how was Apple completely unaware of an accident at Catcher that led to the hospitalization of over 90 workers? How can they claim violations ranging from insufficient training to lack of personal protective equipment are not occurring at Catcher?

There are two possibilities for why this might be. The first possibility relates to the widespread and well known problem in China of corrupt audits: Apple employees might be corrupt. The second possibility is that Apple is purposefully ignoring the rampant problems present at Catcher.

Jiangsu Media Reports (May 25, 26, 27)

Suqian's official safety supervision department issued Catcher an order to cease manufacturing. However, when Catcher received this order, they forced workers to continue working in the affected workshop, resulting in the poisoning and hospitalization of an additional 30 workers. (

Source: https://item.btime.com/039pp86h0kr124mgae8ec47ji5m)

Gas Poisoning

-

On May 25, 2017 at around 4 AM, an incident of a gas poisoning occurred at Suqian Catcher Technology

-

All hospitalized workers worked at Catcher’s A5 and A6 workshops

-

Workers were unable to swiftly evacuate the affected workshop and were required to follow standard check out procedures in order to leave the workshop

-

Around 80 workers were hospitalized, 63 workers had to stay overnight for further observation

-

The morning after the initial incident, the number of workers hospitalized increased to over 90

-

An interviewed staff member from Catcher said that a person who was exposed to the gas would suffer minor burns to their respiratory airway

Catcher Ignored Official Orders

-

The Production Safety, Supervision & Management Office of the Suqian Sushe Industrial Park Administrative Committee issued Catcher an order to halt operations in the affected workshop

-

Catcher Technology ignored this order, leading to additional workers falling victim

-

The safety supervision department of Suqian arranged for experts from an inspection company and the disease control center to conduct thorough investigations of Catcher

High Labor Intensity

Bloomberg Technology

Lack of Personal Protective Equipment

-

Workers are not provided with personal protective equipment such as goggles and earplugs

-

Metal particles and coolants sometimes splash into workers’ eyes

-

Workers suffer headaches from the excessive noise in the workshop

-

Workers in the sand-blasting workshop are provided with one active carbon face mask but the masks quickly clog up

-

Workers are only provided with thicker 3M-branded face masks when the factory will be inspected but high temperatures make wearing the masks unbearable

-

The provided rubber gloves do not last for the entire shift, forcing workers to purchase their own pack of disposable gloves but these gloves quickly become corroded

-

Air filters installed in the cutting machines are ineffective at clearing the vapors produced by slicing metal

Poor Living Conditions

-

Workers sometimes go days without showering due to lack of available showers or hot water

-

Showers are separate from the dorms, workers must walk outside to take a shower

Unfair Treatment of Contracted Employees

Lack of Training

-

Interviewed workers stated that there was a lack of training about the materials used in the manufacturing process

-

Some workers said they were asked to sign forms indicating they had completed the required 24 hours of training when they had not

-

There is a lack of standard operating procedures at Catcher, leading to workers being unsure of how to protect themselves in a dangerous work environment

China Labor Watch

Lack of Personal Protective Equipment

-

Excluding the workers who wear glasses, all other workers in the workshop operate machinery with no eye protection.

-

Workers come in contact with toxic substances, and factory does not specify what the chemicals are and the potential hazards

-

Excessive amount of loud noise at the workshops of the CNC department, which can cause irreversible damage to workers’ hearing.

-

CNC machine operators come in contact with cutting fluid. Despite workers receiving a pair of gloves every day, the gloves quickly absorb a lot of chemical oil and fluids, which would erode the plastic gloves worn inside. Workers’ bare hands will then make direct contact with the cotton glove which has been soaked with cutting fluid, resulting in the skin around the hand becoming irritated and peeling off.

-

The CNC workshop provides workers with cotton gloves which appear to be used, as the gloves are damp and have water stains.

-

For workers who use pressure guns in the production process, the cutting oil splashes onto their heads. Paper face masks provided by the factory only protects the workers’ mouths and faces and the cutting fluid often splashes into the workers’ eyes, which can result the eyes becoming bloodshot, long-term.

Lack of Training

-

The factory requires training to be 24 hours long but actual training is not even an hour in length; workers are handed a questionnaire and staff read out answers. Workers are unaware of potential risk factors during the production process

-

Workers are not provided with substantial safety training.

-

Workers are not informed of the potential harm cutting fluid may have on their bodies or of any relevant protection methods.

Unfair Treatment of Contracted Employees

-

Workers applying through labor dispatch do not have social insurance during their probationary work periods; social insurance cards are only given out to workers after working for three months, if a worker falls ill within those three months, they must pay out of pocket to see a doctor

-

Resignation is difficult for dispatch workers. Workers sent by the dispatch company who apply for resignation are rebuked by Catcher employees and the labor dispatch company will usually not agree to a worker’s request to resign

Physical Examination Fees Are Not Covered

Unhygienic and Unsafe Work Conditions

-

There have been cases where workers have discovered hair in their food, and many instances of workers who suffer a case of diarrhea after eating at the factory cafeteria.

-

Bathrooms do not have enough hot water and many workers during the winter have to shower in cold water. Workers have fallen ill due to the lack of heating and shelter from the wind in the wide-open shower areas.

-

Workshop’s main door only opens 30 cm wide which poses a safety hazard

-

Dorms do not have emergency hallways or exits

-

Ground’s surface is covered in oil, resulting in workers slipping and falling.

Environmental Pollution

High Labor Intensity

Resigning is Difficult

Lack of Transparency With Workers

-

Lack of effective unions – workers are unaware of who their representative is, and if meetings have been held.

-

Workers are not allowed to print out a copy of their attendance records

-

There was a case in November 2017 when some workers were not able to receive their pay stubs allegedly because of a malfunctioning of the printer.

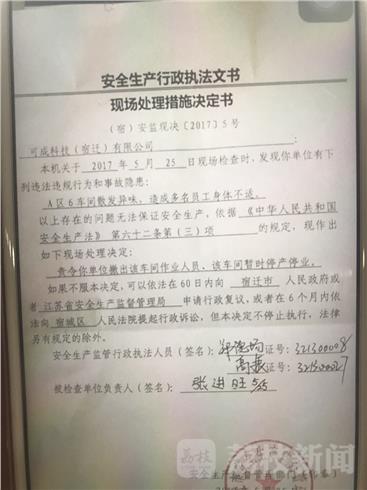

Administrative Law Enforcement of Production Safety

Decisions Regarding On-site Treatment Measures

(Su) Safety supervision department’s decision (2017) No. 5

Catcher Technology (Suqian) Ltd. Co.

When our department conducted an on-site investigation on May 25th, 2017, the following violations of laws and regulations and potential safety hazards were discovered at your company:

There was a strange odor permeating throughout Workshop 6 of Sector A, resulting in health issues for multiple employees.

The above-mentioned problems means production safety cannot be guaranteed. According to Section 62, Article 3 of the “People’s Republic of China Production Safety Law”, the following decisions for on-site treatment measures must be implemented:

Our department orders your company to remove all workers from the affected workshop and for the affected workshop to temporarily suspend operations.

If dissatisfied with this decision, as according to law, your company can apply with the Suqian City People’s Government or Jiangsu Province Safety Production Supervision and Management Office for an administrative review within the next 60 days, or, as according to law, apply with the Sucheng District’s People’s Court for an administrative appeal within the next six months. However, the enforcement of this decision will not cease to be enforced, except as otherwise stipulated in the law.

Administrative Law Enforcement Officer, Production Safety Supervision Department (Signature): Zhen Dechang ID Number: 321300008

Administrative Law Enforcement Officer, Production Safety Supervision Department (Signature): Gao Zhen ID Number: 321300027

Safety Inspection Official (Signature): Zhang Jinwang, May 25

(Translated by China Labor Watch )