Something's Not Right Here: Poor Working Conditions Persist at Apple Supplier Pegatron

Executive Summary

In an interview with PBS journalist Charlie Rose in September 2014, Apple CEO Tim Cook was asked what values he considers most important beyond those of Apple.[1] Mr. Cook responded:

Treating people with dignity. Treating people the same. That everyone deserves a basic level of human rights, regardless of their color, regardless of their religion, regardless of their sexual orientation, regardless of their gender. That everyone deserves respect.

Right now, in Shanghai, China, a factory owned by the Taiwanese Pegatron Group is pushing out millions of units of the iPhone 6s for Apple. There, its young production workers toil six days a week in 12-hour shifts. Each day they are paid for 10 and half hours of work, not counting 15 minutes of unpaid meetings. The mandatory overtime shift runs from 5:30 pm until 8:00 pm. Most workers will not eat dinner before doing overtime because the 30-break given for a meal is not enough time.

Before overtime pay, workers making the iPhone earn only the local minimum wage of $318 per month, or about $1.85 per hour. This is not a living wage. Even if the factory did not mandate overtime as it does, workers would still depend on their 60-hour workweeks to get by.

After their long shifts, workers take a 30-minute shuttle bus back to their dorms where up to 14 people are crammed into a room. Mold grows pervasively along the walls. Bed bugs have spread throughout the dorm, and many workers are covered in red bug bites.

In his interview, Mr. Cook went on:

One of the best ways you can make sure that things are happening well is if people stand up and say, "Something's happening that's not right here." We've audited so deep in our supply chain. We do it constantly, looking for anything that's wrong, whether it's down to the -- there's a safety exit blocked.

While working undercover at the Pegatron factory in Shanghai, CLW’s investigator was never told the locations of emergency exits and never participated in an emergency drill. In fact, at the massive production facility, which employs up to 100,000 people, the investigator never even located an emergency exit.

Despite providing only about eight hours of pre-job safety training—where Chinese law requires 24 hours—Pegatron forces each new worker to sign a form that “certifies” that she has undergone 20 hours of safety training. A worker also must sign a trainer’s name on the form. The factory has workers quickly copy answers to the safety information quiz. These falsified forms are the types of documentation that are provided to Apple in their audits.

The production of an iPhone involves a great number of chemicals. Pegatron gives new workers an information sheet that contains a short list of toxic substances, including cadmium, mercury, hexavalent chromium, and arsenic.[2] Yet no one tells workers anything about the location of these or other substances in the production process or how a person should protect herself from injury.

Something’s Not Right Here

Apple earned about $40 billion in profit last year. Its final quarter in that year, during which the company pulled in $18 billion, was the most lucrative quarter in the history of mankind. Apple is on course to earn over $50 billion in 2015.[3]

Mr. Cook is right when he encourages people to stand up and say, “Something’s happening that’s not right here.” But Mr. Cook has yet to clearly hear and respond when we say it: Something’s not right about the way Apple is doing business.

A portion of Apple’s historical profits is squeezed out of the low pay and illegally poor working conditions of over a million Chinese workers. In February 2015, a CLW report suggested that even using the most conservative estimates, Apple would need to invest up to 10 percent of its profits to ensure that workers making its products enjoy fundamentally improved working conditions. Yet the low pay, long hours, unpaid work, poor workplace safety, and despicable living conditions persist.

Something’s not right here.

Half of the workers hired at Pegatron are temp workers, though Chinese law only permits 10 percent of a workforce to be temporary labor. Under short-term contracts, these workers are treated as though they are disposable.

Something’s not right here.

CLW’s Investigative Results: Two Years with Little Progress

In July 2013, CLW published an in-depth investigative report on working conditions in Shanghai and Suzhou-based factories of Pegatron Group. The report, Apple’s Unkept Promises, detailed an array of serious labor rights violations and compared the reality of working conditions in Pegatron plants to the commitments that Apple publicizes in regard to labor rights.

In the two years subsequent to the report, CLW also documented several cases of the sudden deaths of young iPhone workers due to abnormal or unexplained causes at Pegatron Shanghai. One instance was that of a child worker, Shi Zhaokun, who often worked 13 hours a day before his sudden death from pneumonia in October 2013. Another worker, 26-year old Tian Fulei, died in February 2015 of what the hospital deemed “sudden death.” Both workers had been employed on Pegatron’s iPhone production lines.

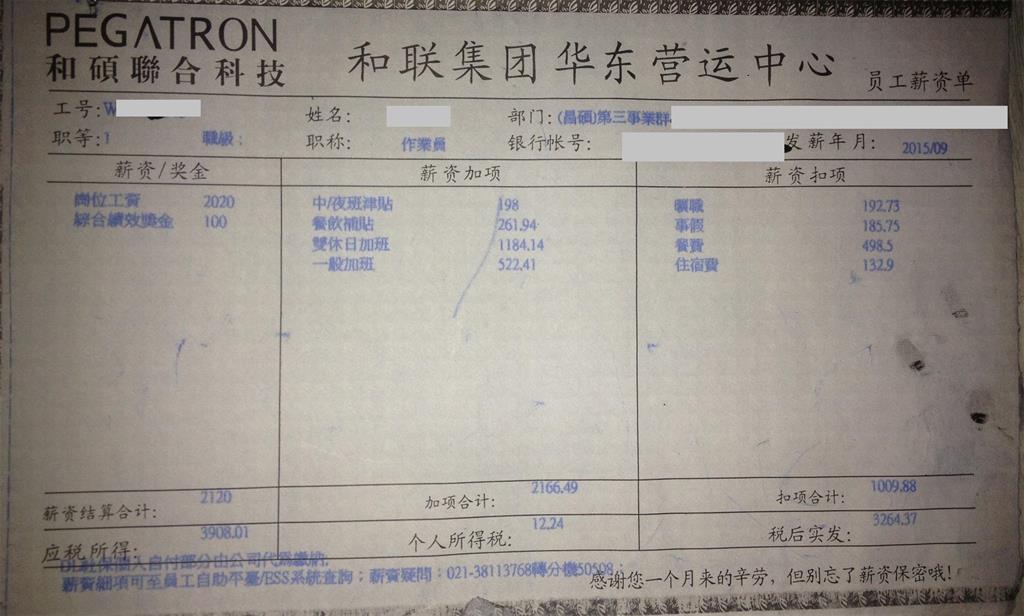

In September and October 2015, CLW conducted a new investigation of the working conditions at Pegatron’s Changshuo factory in Shanghai, which is currently producing the iPhone 6s. Findings are based on undercover research by a CLW investigator who was hired at Pegatron as a production line worker, as well as the calculation of data from 127 Pegatron worker pay stubs, about two-thirds of which cover working hours and wages from September 2015. During the investigation, CLW conducted dozens of interviews with Pegatron workers.

CLW’s newest investigation reveals 23 categories of legal and ethical labor rights violations at Pegatron Shanghai.

Applicants must pay for their mandatory pre-job physical exam. Despite Pegatron forcing workers to sign forms verifying that they have undergone 20 hours of pre-job safety training, workers only participate in eight hours of training. The Chinese statutory minimum is 24 hours. Moreover, the training does not touch upon the specific toxic chemicals which workers may handle every day. Pegatron even hands out information to new workers that lists a number of hazardous chemicals, including arsenic, hexavalent chromium, mercury, cadmium, and lead. Despite the significant toxicity of these chemicals, factory personnel provided no further information about the way in which these chemicals are used at Pegatron, the possible harm to human health, or how workers can protect themselves. Workers do not always receive protective equipment, and even if they do, a lack of awareness leads many people to use the equipment improperly.

Part of the risk to workers’ health is posed from excessive working hours. CLW’s investigation shows that in 2015, Pegatron Shanghai workers’ median overtime per month was 80 hours (83 hours in the busy season). During their 12-hour shifts, workers are given only 50 minutes for lunch and 30 minutes for dinner; the second meal break is so short that most workers forego dinner until they clock-out after 8 pm. CLW’s investigator worked on one iPhone motherboard unit every 3.75 seconds, standing for the entirety of his 10.5 hours of daily work. When the worker next to them takes lunches and dinners, workers must pick up their neighbor’s workload. Laboring under this schedule six days per week, during the busy season Pegatron workers earn about 4,000 RMB ($629) per month, of which approximately 1,750 RMB ($275) is overtime pay. In addition to this low-wage exploitation, the workers are required to attend unpaid meetings, equating to 15 minutes of unpaid overtime each day (6.5 hours per month).[4]

Pegatron tells its employees that it pays for both the employer and employee portions of mandated insurance contributions. Yet workers cannot verify the insurance contributions through their pay stubs, which no longer include any information about workers’ insurance. Pegatron’s employee service center also does not provide insurance figures. Furthermore, Pegatron does not contribute to workers’ housing funds, a mandatory benefit under Chinese law.

The poor conditions do not end in the workshop. Pegatron workers’ dorms house up to 14 people per room, where dark mold spreads along the walls and bed bugs are rampant.

Pegatron Shanghai Investigations: 2015 vs 2013

Unfortunately, the awful working and living conditions that Pegatron workers face in 2015 are generally no better than those witnessed in 2013. CLW compared 21 categories of findings from the 2013 and 2015 investigations of Pegatron Shanghai. Only one category revealed fundamental improvement: Whereas in 2013 Pegatron explicitly maintained discriminatory hiring practices against people of Tibetan or Uyghur ethnicity, people with dyed hair, and people over 35, in 2015 CLW did not observe such practices. (We note here that there is an unconfirmed issue of Pegatron’s policies toward women who are pregnant or preparing to become pregnant.[5])

In four other categories CLW found partial improvement. For example, if we compare September (typically a busy season) working hours from Pegatron pay stubs in 2015 and 2014, there has been limited improvement. The average workweek dropped from 63 hours to 60 hours. The percentage of compliance with Apple’s 60-hour workweek has risen from 7% in 2014 to 42% in 2015. In September 2014, 50% of workers put in over 90 hours of overtime for the month, but a year later, only 32% had done so. The maximum overtime recorded dropped from 130 hours to 119 hours. Despite these limited changes, 58% of workers continued to have workweeks in excess of Apple’s 60-hour workweek standard in September, and if we were to include the 90 minutes of unpaid meetings workers must attend per week, then the proportion of workers in excess of 60-hour workweeks would be notably higher. In any case, Apple’s 60-hour workweek does not conform to China’s overtime hour maximum. A 60-hour workweek equates to approximately 85 hours of overtime per month, but Chinese regulations allow no more than 36 hours.

11 of 21 categories of findings compared between 2013 and 2015 have not seen any meaningful change. For instance, temp workers are still used in proportions high above the legal maximum of 10%, pre-job safety training is still far short of the 24-hour minimum, some documentation related to working conditions continues to be fraudulent, and workers are still unpaid for daily meetings.

Most concerning is that based on CLW’s investigative findings, in five of 21 categories, problems have further deteriorated since 2013. Meal times are even more compressed than they were in 2013, now with only 30 minutes for dinner instead of 40 minutes. CLW did not collect any information about fines on workers in 2013, but in 2015’s probe documented fines of 50 RMB ($7.86) to 300 RMB ($47) for behaviors like crossing one’s legs or forgetting to wear one’s work ID. And the already crowded dorms now have a bed bug infestation.

The figure to the left demonstrates the comparison of categories from 2013 to 2015. It is important to note that in 2013, CLW’s investigator at Pegatron in Shanghai was hired via dispatch company, whereas in 2015 the investigator was hired directly. This means that additional violations may not have been documented in 2015, such as hiring discrimination against temp workers or dispatch companies failing to pay all wages and insurance for temp workers.

NOTE: Detailed chart in Appendix B in the PDF report.

Apple Must Live Up To Its Legal and Social Responsibilities

CLW has previously detailed how Apple has the greatest control of working conditions among all actors in its supply chain. It is not a question of whether Apple must ensure that workers making its products enjoy fair and safe working conditions. It is only a question of when Apple will make good on its commitments.

CLW believes that if Apple institutes the following measures throughout all of its suppliers, it will have taken a significant step toward improving workers’ conditions:

- The specific amount of social insurance paid to workers should be transparent to them, included on their pay stubs and available when workers make inquiries to the company;

- Factories should provide all mandatory insurance in full, including the housing fund;

- Factories should restrict the hiring of temporary (or dispatch) labor at a given factory to no more than 10% of the workforce, in compliance with Chinese law;

- Workers should not be made to work without corresponding pay;

- The base wage rate should be increased significantly above the local minimum wage so that workers do not need to depend on overtime to make a living;

- Worker housing should be hygienic and more spacious;

- Pre-job safety training should last for at least 24 hours, as required by law, and workers should be taught specifically what chemicals and hazards they will encounter in their positions and how to mitigate health risks;

- All workers should receive appropriate protective equipment and be taught how to properly use it before beginning work;

- Industrial processes should be adjusted to allow workers a chance to both stand and sit or lean while they work;

- Factories should ensure that workers have pre-job, on-the-job, and pre-resignation physical exams, as required by law, for which the factory pays for all fees;

- Let workers elect enterprise-level union representatives that can actually represent worker interests.

[1] Full transcript of the interview: http://www.businessinsider.com/tim-cook-full-interview-with-charlie-rose-with-transcript-2014-9

[2] China

RoHS (Restriction of the Hazardous Substances in electrical and electronic equipment) is a set of standards based on previously instituted European Union standards (the latest version of which is 2011/65/EU), which restricts the use of six substances: lead (Pb), cadmium (Cd), mercury (Hg), hexavalent chromium (Cr(VI)), polybrominated biphenyls (PBBs) and polybrominated diphenyl ethers (PBDEs). Pegatron’s requirement of the chemicals in general fall below the RoHS limits, but it RoHS standards only represent chemical contents in final product, not worker exposure during production processes. In addition, Pegatron’s arsenic standard is 1,000 ppm, far above the safety exposure limit recommended by NIOSH in the United States (50 ppm). A more detailed description of these chemicals and the hazards posed to human health can be found on page 25 of this report and in Appendix A.

[3] “How Apple could make a $53 billion profit this year,” CNN Money. http://money.cnn.com/2015/07/17/technology/apple-earnings-2015/

[4] See Appendix C in the PDF report for statistics on the 127 Pegatron worker pay stubs.

[5] Women who are pregnant or preparing to become pregnant are told to identify themselves during pre-job physical exams. Pegatron ostensibly wants to prevent unborn children from being affected by radiation produced in x-ray procedures, but there is currently no scientific evidence clarifying that a typical x-ray test poses a risk to a women’s ovum. During the investigation, women who said they planned to become pregnant soon were separated from the investigator’s group of applicants, and CLW was unable to confirm whether those women were hired by Pegatron.