The Other Side of Fairy Tales: An investigation of labor conditions at five Chinese toy factories

Executive Summary

The joyful fairy tales associated with many toys are belied by the tragic stories woven into toy production. In workshops that are hazardous to their health, millions of workers toil under cruel management, 11 hours a day, six days per week. Over the course of a year, a toy worker may only be able to see her parents and children one time. Making the minimum wage, workers must bear such conditions just to get by.

Many workers at one toy factory did four-hour shifts without taking a break for water or the restroom. When asked why, the workers explained that it wasn’t possible to take water breaks with so much work to do. A worker named Ms. Li at another toy plant is only five years from retirement. She found out that management had a policy to push out workers close to retirement in order to avoid pension payments. For Ms. Li, this policy means that she may be left without the full amount of her earned retirement funds. She said knowing this keeps her awake at night.

Toy manufacturing has been in China for more than 20 years. A 2015 report from HKTDC Research states that 75% of toys globally are produced in China.

[1] According to a report from the U.S. Department of Commerce, 85% of U.S. toy consumption, worth $22.2 billion, came from Chinese imports in 2010.

[2] Yet CLW’s most recent set of investigations have found that poor working conditions in Chinese toy factories continue. The toy companies implicated in the investigations includeHasbro, Mattel and Mattel-owned Fisher Price, McDonald’s, Jakks Pacific, Disney, NSI Toys, Battat, and MGA Entertainment. Some of the toy brands observed during the investigation include Frozen, Monster High, Nerf, Marvel, Star Wars, Wubble Ball, Fur Real Friends, Hot Wheels, and Lalaloopsy. Most of these toy products are sold at U.S. retailers like Walmart.

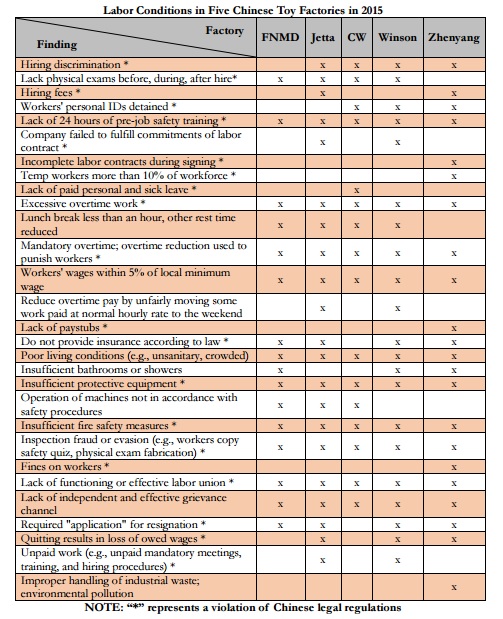

There are more than one thousand toy manufacturers in China. From to May to July 2015, CLW conducted in-depth investigation into five major factories: Foshan Nanhai Mattel Diecast Company, Jetta (Guangzhou) Industries, Combine Will (Dongguan) Industrial Company, Winson (Taiqiang) Precision Manufacturing (Shenzhen) Company, and Dongguan Zhenyang Toy Company. Altogether, the factories employ over 20,000 workers. CLW’s investigators were sent into each of the factories to carry out undercover research as frontline production workers. Some of these plant have been investigated by CLW in past years, which enabled a comparison of working conditions over time (see pages 8, 10 of

PDF report).

The Other Side of the Fairy Tales

The story of toy factories reflects a yawning gap between the fairy tale and the reality of toys. Toy brands play toy manufacturers off one another to reduce production prices and maximize profit margins. The competition leads to declining conditions for workers in toy factories. This dynamic ultimately reveals the emptiness behind toy brands' much-promoted commitments to ethical procurement and labor conditions. Worldwide auditing to implement the code of business practices of the International Council of Toy Industries (ICTI) began in 2002. Mattel’s code was established in 1997. Yet in 2015, we continue to observe toy workers regularly confronted with illegal and unfair employment practices.

Chinese toy workers regularly protest against their poor treatment. During the period of investigation, Jet Fair Industrial Limited (Jingyu Toys), a supplier factory to Hasbro, Mattel, and Walmart, experienced a strike of about 100 workers who demanded severance compensation and insurance back pay from the factory before its impending relocation. The action was ultimately unsuccessful, and some workers were detained by police. (A response from the toy industry group ICTI to CLW’s report on Jet Fair is in Appendix A in the

PDF report.)

In August, at Ever Force, a Mattel supplier plant, the owner ran away after the company's business stalled. Hundreds of workers were unable to obtain three months' wages and four months' insurance contributions, an amount totaling about $700,000. This drove workers to risk a march on the local government to demand assistance. The government dispatched a large contingent of riot police and K-9 units to suppress the workers' action and compel them to accept partial compensation. In a weak position, most of the toy workers had no choice but to “discount” their labor. The Wall Street Journal later reported that Mattel had already known months before the strike that the Ever Force factory was in a critical state.

In September, a Disney toy supplier based in Shenzhen closed down, causing hundreds of workers, already owed about $1.5 million in severance and insurance compensation from the factory, to lose their jobs. Instead of protesting in China, where such actions are prohibited, some of the toy workers traveled to Hong Kong, where they demonstrated at Disneyland to protest Disney's disregard for workers' rights.

These photos were taken at a workers’ strike that occurred in early August 2015 at the

Dongguan-based Ever Force Toys and Electronics Company factory, a major supplier for Mattel.

Riot police and K9 units were deployed to put down the demonstration.

Sources: social media

In a brief review of open news sources, CLW calculated 56 cases related to fires and occupational injury (30), deaths (14), demonstrations (16), and child labor (5) in Chinese toy factories. For instance, in 2007 more than 300 middle school students, some child labor under 16, were discovered toiling 11 hours a day at a plastic toy factory. Several students’ health suffered as a result of long hours and chemical poisoning; one female student even died. In 2011-12, more than one hundred workers were poisoned by benzene at a toy factory with clients that included Disney, Mattel, Hasbro. (See Appendix B in the

PDF report for a full list of Chinese toy industry incidents.)

When instances like those described above of rights violations and worker strikes occur in toy factories, brand companies typically deny any relationship to the injustice and push responsibility onto their supplier factories.

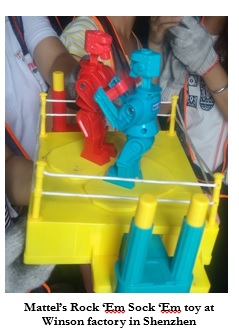

The damage after a major fire in a painting workshop at Winson, which occurred in May 2015.

The workshop was producing Mattel’s Rock ‘Em Sock ‘Em toy.

Thus is the state of toy product supply chains. Brands demand the best quality, the fastest production time, and the lowest costs, with no regard for how their demands affect the lives of workers. The ethical purchasing standards flaunted by brand companies are simply a marketing tool. In two decades of toy production in China, poor working conditions have not fundamentally improved. The results of CLW’s 2015 investigation, summarized below in a table, demonstrate the severity of the problem.

The myriad labor abuses listed above are the consequence of brand companies demanding the lowest production price and toy factories minimizing labor costs. The corporations maximize shareholder and executive profits by squeezing costs. Ultimately, the price is paid by workers.

A clear example of this dynamic is a manipulative practice utilized by some toy factories that equates to wage theft. CLW’s investigations revealed a practice in both the Winson and Jetta factories whereby regularly paid working time was “diverted” onto Saturdays, thus reducing weekend overtime pay—double the normal rate—paid to its workers.

[3] Employing up to 11,000 workers, the two companies may be cheating workers out of $1-2 million a year.

In years past, Mattel’s directly owned Chinese factories used the same type of working hour manipulation to reduce workers’ overtime wages—for example, Mattel Electronics Dongguan (Radica) in 2008. CLW’s recent investigations of Mattel’s directly owned plants have not found the same sort of wage theft, which is a welcomed improvement. Unfortunately, Mattel’s suppliers, such as Winson, continue to cheat workers out of hard-earned overtime pay.

Earning paltry wages, toy workers depend on overtime, expending their bodies and time in 60 to 80-hour workweeks. Even with such massive amounts of overtime, a toy worker can only earn 1/2000 of the value of each toy she works on. Based on information collected in CLW’s investigation, if we combine all wage remuneration a toy worker receives, that worker will earn less than 2 cents USD for each toy that she produces.

[4]

At Mattel’s Shenzhen-based supplier plant Winson, if a worker does 110 hours of overtime a month, working on 40,320 toys, she will earn $0.016 per toy. The classic Mattel toy brand Rock ‘Em Sock ‘Em, which was being produced at Winson during this investigation, retailed on Amazon at $30 in October 2015. This means that each Winson worker earns only 0.05% the market value of the Rock ‘Em Sock ‘Em toy. Workers produce nonstop. Young workers sacrifice their youth and health, and working parents often only have a chance to see their families and children once a year. Despite such sacrifice, a worker earns only 1/2000 the value of a toy she produces.

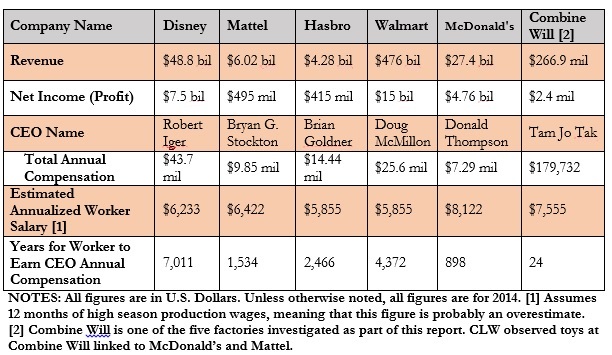

While workers struggle year after year to survive, the corporations above them exploit workers’ labor to enlarge the fortunes of shareholders and executives. In 2014, Disney’s revenue and profit reached $48.81 billion and $7.5 billion, respectively. That same year Disney CEO Robert Iger’s total compensation of $43.7 million made him the 12th highest paid CEO in America, according to The New York Times.

[5] This means that a Chinese worker making Disney’s toys would need to work 11 hours a day, six days a week for 7,011 years to earn the annual compensation of Disney’s CEO. For Mattel and Hasbro, the comparable figures are 1,534 and 2,466 years, respectively.

Limited Improvements in Working Conditions

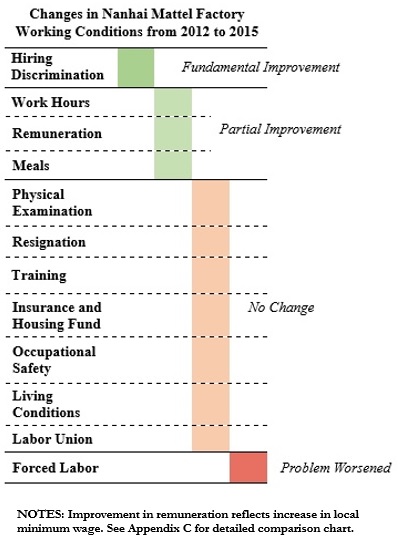

As explained above, there has been no fundamental change, generally speaking, in working conditions in the toy industry over time. However, if we compare CLW’s previous investigations with the results of the 2015 investigations, limited improvements can be observed. For example, if we compare CLW’s 2012 investigation of Foshan Nanhai Mattel Diecast Company (“FNMD”) with its 2015 investigation across 12 categories of working conditions, one category saw a fundamental improvement—i.e., FNMD has not only reduced its illegal practice of hiring discrimination of applicants, it even actively recruits individuals with disabilities. Three types of working conditions saw a partial improvement—for instance, while working hours continue to exceed legal maximums, daily working hours have apparently been reduced by an hour, from 11 hours in 2012 to 10 hours in 2015.

While there has been some progress, FNMD was found to have seven types of working conditions which failed to improve in the three years since the last investigation. For instance, there continues to be major problems in the distribution and proper usage of protective equipment, and FNMD still has no effective labor union. Even more concerning is that FNMD has one rights violation that has further deteriorated since 2012: Not only are Mattel workers obligated to work overtime, but as of 2015 they are forced as a condition of hiring to sign a form which signifies that they voluntarily accept all overtime arrangements.

Moreover, management will use the reduction of overtime hours—and thus overtime pay—to punish workers.

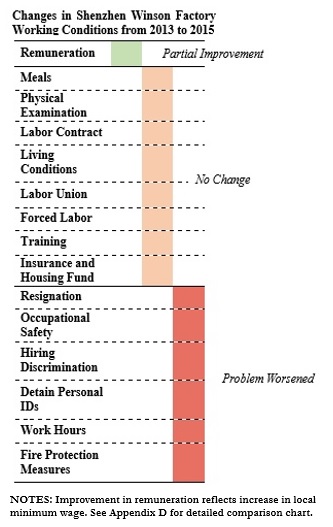

But at Winson Precision Manufacturing (hereafter “Winson”), a Mattel supplier plant in Shenzhen, a comparison between CLW investigative findings in 2013 and 2015 shows that nearly all working conditions have failed to improve or have deteriorated. Among 15 categories of working conditions, not one category witnessed a fundamental improvement, and only one category saw partial improvement: Wages at Winson increased since 2013, but this is simply a reflection of increases in the legal minimum wage, as Winson workers’ base wage is still largely the minimum wage. Eight categories of working conditions at Winson have witnessed no change. For instance, applicants do not receive a physical exam, new workers must wait a week or more after beginning work to sign a labor contract with Winson, and insurance at Winson is optional. All three of these findings represent violations of legally enshrined labor rights in China.

Furthermore, according to this year’s investigative findings, six categories of working conditions at Winson have actually deteriorated. For example, whereas in 2013 Winson would not hire anyone older than 40, this age discrimination has become even more severe with the upper age limit set to 30; Winson also hires discriminatorily based on gender. Fire safety at Winson is a major problem. CLW’s investigation discovered that a major fire occurred at Winson in May 2015, burning out an entire production workshop.

Fundamental Reform

in Toy Factories

As discussed in the summary above, for nearly two decades human rights abuses have continued in Chinese toy factories supplying to the world’s largest toy brands. Comparisons of this year’s investigative findings with past years’ findings demonstrate that few improvements are occurring, and some conditions even are worsening. The largest benefactors of such ongoing abuse are the profitable toy, brand, and retail companies at the top of global value chains. These companies have the power to influence and control labor conditions in toy factories, and they must bring fundamental reforms to the conditions of workers making their beloved toys. Such reforms include but are not limited to:

- Reduce the use of temporary workers to less than 10% of total workforce;

- Workers’ base wages should be increased significantly above the local minimum wage so that workers are not dependent on long overtime hours;

- Production schedules should be adjusted so as to ensure that overtime work is strictly voluntary;

- Resignation should not require “application” and resigning workers should receive due wages upon exit from the factory;

- All activities that are a mandatory requirement or duty of a job should be compensated (including group meetings, training, and required on-boarding procedures);

- Provide workers with more spacious and hygienic housing;

- Ensure that workers receive pre-job that is 1) in accordance with legal requirements and 2) sufficient to educate them on all chemicals or procedures which could pose a risk to their short- and long-term health;

- Other legal violations mentioned in this report should be remedied;

- Let workers elect enterprise-level union representatives that can actually represent worker interests.

ENDNOTES FOR EXECUTIVE SUMMARY

________________________________________________

[1] HKTDC Research, “中国玩具市场概况”, 24 July 2015, http://china-trade-research.hktdc.com/business-news/article/%E4%B8%AD%E5%9B%BD%E6%B6%88%E8%B4%B9%E5%B8%82%E5%9C%BA/%E4%B8%AD%E5%9B%BD%E7%8E%A9%E5%85%B7%E5%B8%82%E5%9C%BA%E6%A6%82%E5%86%B5/ccm/sc/1/1X000000/1X002MRF.htm

[2] U.S. Department of Commerce Industry Report: Dolls, Toys, Games, and Children’s Vehicles NAICS Code 33993, http//www.toyassociation.org/app_themes/tia/pdfs/facts/2012toyoutlook.pdf

[3] Chinese law stipulates that workers must be paid overtime wages for time worked in excess of 40 hours a week and that weekend overtime be paid at a double-time rate. Factories typically run a 5-day workweek comprised of 8-hour workdays with overtime on Saturdays paid at a double-time rate. But at Winson and Jetta, despite its workers doing the same long overtime hours as other factories, management intentionally uses a different time recording method to “divert” normally paid working time to Saturdays, thus reducing work paid at a double-time rate.

[4] For example, at Mattel’s Shenzhen-based supplier plant Winson, one production line maintained a daily quota of 1,600 toys, and each worker on the line will work on each of the 1,600 toys. Working six days a week, 4.2 weeks a month (assuming a 30-day month), a Winson worker will be expected to produce 40,320 toys per month. The worker’s base monthly wage (i.e., before overtime) is the local minimum wage of 2,030 RMB ($319). After adding in all other high-season remuneration, including overtime, and before taking deductions, a worker’s income may reach 4,060 RMB ($638) per month—this assumes 110 hours of overtime. If we divide monthly income (4,060 RMB) by the number of toys produced (40,320), we reach the conclusion that each Winson worker earns 0.100069 RMB ($0.016) per toy.

[5] Highest-Paid Chiefs in 2014, The New York Times, http://www.nytimes.com/interactive/2015/05/14/business/executive-compensation.html