Apple’s Failed CSR Audit :A Report on Catcher Technology Polluting the Environment and Harming the Health of Workers

Executive Summary

Catcher Technology (Suqian) Co Ltd. is a world leader in the light metal industry, specializing in notebook computers, digital cameras, and disc drives. Headquartered in Taiwan, the company has set up a number of mainland branches. Catcher manufactures products for Apple, IBM, Dell, HP, and Sony, amongst other well-known brand companies.

In 2014, China Labor Watch released an investigation reportat Catcher Technology, which outlined a string of rights violations including discriminatory hiring policies, lack of safety training, long work hours, and low wages. From October 2017 to January 2018, China Labor Watch conducted another in-depth investigation into the working conditions of the Catcher factory based in Suqian.

CLW identified major issues at Catcher regarding occupational health and safety, pollution and work schedules. On the morning of May 25 2017, there was an incident of toxic gas poisoning at Catcher’s A6 workshop, which resulted in the hospitalization of 90 workers, with five workers admitted to intensive care. Shortly after, the Administrative Committee of the Suzhou-Suqian Industrial Park, located in Suqian city, Jiangsu Province, conducted an investigation and the results of the committee’s investigation can be found

here.

( Currently, over 90 workers are hospitalized and receiving emergency treatment. 6 workers are receiving intensive emergency care. Source: http://news.jstv.com/a/20170527/148730.shtml )

(Suqian's official safety supervision department issued Catcher an order to cease manufacturing. However, when Catcher received this order, they forced workers to continue working in the affected workshop, resulting in the poisoning and hospitalization of an additional 30 workers. Source:

https://item.btime.com/039pp86h0kr124mgae8ec47ji5m)

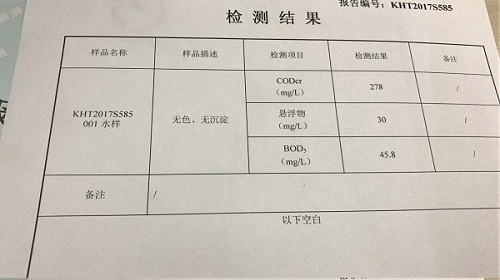

During the investigation period, CLW discovered that the factory's wastewater had a lot of white foam, which was directly dispensed into the public sewage system. CLW first consulted with related experts and testing companies on water quality testing procedures. On December 26, we then collected a 600ml sample of the factory's wastewater and tested for levels of Chemical Oxygen Demand (CODcr), Biochemical Oxygen Demand (BOD) and Suspended solids (SS) – three common measures for water quality - at Suzhou Kunhuan Detection Technology Co., Ltd. On January 4, we received the results of the tests, and discovered that the water had exceeded the CODcr, BOD and SS levels stipulated by the local government. The results showed that the water had CODcr levels of 278mg/L, well above Jiangsu's standard of 80 - 120mg/L. BOD levels were at 45.8mg/L which also exceeds the 20 - 30mg/L standard. Jiangsu’s standards regarding water quality can be found

here.

Test results of CODcr, BOD and SS on the factory’s wastewater

A map of the location where the wastewater was collected for testing

Wastewater with white foam overflowing onto the sidewalk where the test sample was collected

Everyday, from when the investigator first entered the factory on October 8th until the day the wastewater sample was collected on December 26th, there was new wastewater overflowing onto the sidewalk

The Catcher factory schedules Saturdays as overtime with workers being paid double time, and Sundays as days off. However, the factory has now adopted a "seven shifts, six rotations" work schedule. From Monday to Friday, workers take turns in having a day off; which means that workers have their day off earlier in the week but then make up that day of work later on. Saturdays are used to make up and is therefore not paid double time, and Sundays are still counted as regular workdays. Workers affected by this schedule lose around 500 RMB ($76.57 USD) every month in overtime pay.

CLW brought up a number of issues regarding Catcher with Apple, however, Apple claimed that the factory had undertaken and passed over 50 audits.

Suqian Catcher’s working conditions include the following:

- Workers are responsible for paying for the physical examination. Workers do not undergo a physical examination after they resign and if workers contract an occupational disease, it would be difficult to determine whether this was a result of working at the factory

- The factory requires training to be 24 hours long but actual training is not even an hour in length; workers are handed a questionnaire and staff read out answers. Workers are unaware of potential risk factors during the production process

- Wages not settled day of resignation as legally required and are only distributed on the 5th of the following month

- Resignation difficult for dispatch workers. Workers sent by the dispatch company who apply for resignation are rebuked by Catcher employees and the labor dispatch company will usually not agree to a worker’s request to resign

- Catcher’s work regulation pamphlet specifies an eight hours a day, five days a week work schedule but working hours are generally 10 hours a day, six days a week

- Base wage of 1950 RMB

- There was a case in November 2017 when some workers were not able to receive their pay stubs allegedly because of a malfunctioning of the printer.

- Violations regarding social insurance. Workers applying through labor dispatch do not have social insurance during their probationary work periods; social insurance cards are only given out to workers after working for three months, if a worker falls ill within those three months, they must pay out of pocket to see a doctor

- There have been cases where workers have discovered hair in their food, and many instances of workers who suffer a case of diarrhea after eating at the factory cafeteria.

- Bathrooms do not have enough hot water and many workers during the winter have to shower in cold water. Workers have fallen ill due to the lack of heating and shelter from the wind in the wide-open shower areas.

- Workers are not provided with substantial safety training.

- Excluding the workers who wear glasses, all other workers in the workshop operate machinery with no eye protection.

- Workers come in contact with toxic substances, and factory does not specify what the chemicals are and the potential hazards

- Severe pollution at the factory. The investigator worked at the factory for four weeks before having to leave due to respiratory issues.

- Excessive amount of loud noise at the workshops of the CNC department, which can cause irreversible damage to workers’ hearing.

- Ground’s surface is covered in oil, resulting in workers slipping and falling.

- CNC machine operators come in contact with cutting fluid. Despite workers receiving a pair of gloves every day, the gloves quickly absorb a lot of chemical oil and fluids, which would erode the plastic gloves worn inside. Workers’ bare hands will then make direct contact with the cotton glove which has been soaked with cutting fluid, resulting in the skin around the hand becoming irritated and peeling off.

· The CNC workshop provides workers with cotton gloves which appear to be used, as the gloves are damp and have water stains.

- For workers who use pressure guns in the production process, the cutting oil splashes onto their heads. Paper face masks provided by the factory only protects the workers’ mouths and faces and the cutting fluid often splashes into the workers’ eyes, which can result the eyes becoming bloodshot, long-term. Workers are not informed of the potential harm cutting fluid may have on their bodies or of any relevant protection methods.

- Workshop’s main door only opens 30 cm wide which poses a safety hazard

- Dorms do not have emergency hallways or exits

- Lack of effective unions – workers are unaware of who their representative is, and if meetings have been held.

- Factory is polluting environment with wastewater

· Workers are not allowed to print out a copy of their attendance records

Worker cases

a. A young couple from Shaanxi, both of whom are workers in Catcher's B sector. In early November, the woman had a miscarriage. After she left the hospital, the two people brought the hospital's diagnosis report and her medical history to the resignation interview at the Care of Employees Center located at the West Gate of Catcher's B sector. They asked to fill out resignation forms so that they could return to their hometown. The human resources department signed off on the woman's resignation form but refused to approve of the man's resignation application. The man gave a full account of the events. Due to the wife's frail health, she was unable to sit by herself for ten or more hours on a long distance bus. She had to have someone accompany her. He was resigning so they could go back together and he could take care of his wife. The factory only approved her resignation. The human resource staff was firm and would not approve of her husband’s resignation as it was without reason and unjustified. Instead they asked him to talk with the intermediary that introduced him to work at the factory. He called the intermediary and the intermediary also did not approve, saying, "In any case, you can't leave", "Why don't you just miss work and quit?". At the time, the man was furious so he yelled into the phone: "My wife miscarried and had to be hospitalized after working here for two months. Miscarried! Do none of you have any humanity?". Hearing his tone of voice, it sounded like he was near tears. Afterwards, the woman called the intermediary and repeatedly pleaded for over half an hour before the intermediary finally approved of the man's resignation.

After talking with this couple, our investigator began to suspect the miscarriage was related to the workshop's oil smells, excess noise, standing for long periods of time without rest while working among other factors. Their contact information was not obtained.

b. A 26 year old male worker from Suining, Xuzhou had worked at Catcher for approximately three years. He worked in the molding workshop, which is very dusty. After working for a year, he was treated for rhinitis and continued working but in less than a year, the rhinitis returned. In the second half of 2017, the rhinitis returned two, three more times. He was deeply worried and suspected that he had pneumoconiosis. In the middle of December, he quietly missed work and left the factory.

This case was discovered after talking with the workers who lived in his dorm. The molding workshop produces large amounts of metal dust but the factory only provides a thin face mask that is poorly fitted, similar to the single use ones used in hospitals. The masks do not provide any protection and the accumulated dust workers inhale results in illness.

c. A 32 year old female worker from Henan was an operator in Vito's CNC department. She worked in the CNC workshop for around two months and her hearing suffered. Presently, she does not dare to remain in crowded areas as she will become dizzy and irritable. She was not used to the workshop's oil smells and often felt nauseated. She was transferred to different positions and other workshops many times.

CNC workshop produces excess noise and has a heavy oil smell. The personal protective equipment (earplugs, face masks) provided to the workers by the workshop provided only weak protection.

d. The investigator worked in Catcher's CNC production line and assembled/dissembled screws. They worked in the CNC workshop for around a month and their eyes were splashed with cutting fluid and metal particles multiple times, resulting in eye pain and a sensation of foreign substances in their eyes. Their vision also suffered. One month after they resigned, their eyes still remain bloodshot.

The workers in the CNC workshop are supposed to have safety goggles but the operating manual on the CNC machine does not specify this requirement and the workshop does not provide workers with safety goggles.

Results of the Investigation into the Unidentified Gas Discovered May 25th in the A6 Workshop of Catcher Technology (Suqian) Ltd. Co.

The investigation revealed the accident in the A6 workshop of Catcher Technology (Suqian) Ltd. Co (hereafter referred to as Catcher Technology) was caused by the wearing of an air compressor screw leading to a secondary accident of the compressor mechanics malfunctioning. Due to the friction produced by the bearing block and screw locking up within the power air compressor, a large amount of thermal energy was generated and the screw split apart as a result of the lack of internal lubricant. The splitting led to the formation of small molecular hydrocarbons that contained sulfur, phosphorus and other compounds produced by the decomposition of additives, as well as the formation of irritant gases. The gas reached the workstations via the compressor pipe system and permeated throughout the entire workshop, triggering adverse reactions among operator personnel.

Currently, the city’s environmental protection agency and emergency response center as well as Jiangsu Innovative Safety Inspection Co., Ltd, a third-party organization, have continued inspecting the Catcher Technology A6 floor workshop. The inspections carried out in the factory’s surrounding environment and work grounds revealed all the monitored parameters were in accordance with national standards. No abnormalities were discovered. All personnel who suffered adverse reactions have already been released from the hospital.

We are already conducting an investigation into this accident to find all responsible parties. In accordance with the investigation results, the responsible parties and individuals will be dealt with according to the law.

Administrative Committee of the Suzhou-Suqian Industrial Park, located in Suqian city, Jiangsu Province

June 1, 2017